Don’t become Gone with the Wind when you’re building a Bridge on the River Kwai

Don’t become Gone with the Wind when you’re building a Bridge on the River Kwai

Posted on April 13, 2023

Why the fake crane inspector is such a problem and what you can do about it.

Written by Nathan Rasmussen, Consulting Services Manager – Made Safe

Let’s talk about the CSA standards covering crane inspector qualifications and the qualifications of organizations that provide inspection services.

By now, most folks reading this blog will have heard about the person in Ontario now facing 352 charges relating to posing as a licensed engineer (and if you haven’t, don’t worry – you can catch up here). Reports are that at least 80 inspections and non-destructive tests were conducted on cranes and lifting devices in 2021 by this person. The most surprising part is that when I typed, “fake crane inspector,” into Google this morning, there were multiple fake inspectors to choose from!

This issue poses a lot of risk, and to prevent it from happening, we need to start at the beginning: Why do we need special crane inspectors or engineers to inspect our cranes? Your crane operators already conduct a pre-shift inspection of your cranes every day, and in multi-shift operations multiple times a day! Why do you need an inspector who may be unfamiliar with the equipment in the first place?

A crane or hoist that has been inspected by an unqualified individual may be at risk of failing, and you wouldn’t know it until you hear the crash. If your crane has not been inspected as per the standard or the regulation, a shutdown of the crane until it IS properly inspected is a risk. A properly designed crane inspection program, including non-destructive testing, is the most effective way to test equipment for defects from fatigue, structural flaws, and other problems that could lead to serious injury or costly equipment and facility shutdowns.

In Manitoba, here’s how the legislation flows: Part 23.4 of the Workplace Safety and Health Regulation MR 217/2006 requires employers (and suppliers) to ensure that all commercially manufactured cranes and hoists must be (deep Ace Ventura-style breath) designed, constructed, erected, used, maintained, examined, inspected, operated and repaired in accordance with the manufacturer’s specification and the applicable requirements of the following standards.

For our needs today, we’ll just focus on the ones relating to inspection, but feel free to reach out at any time to talk crane – I’m always up to chat about the AMSE standard B30.20.

If you’re looking for information on crane inspection frequency – look no further. Check out our previous post on crane requirements, including frequency of your crane inspections and what needs to be inspected at each interval.

Inspection Organizations

If you take nothing else away from this article, here’s a critical piece: Clause 4.4 of W178.1 says that the Canadian Welding Bureau (CWB) will maintain a list of certified inspection organizations, along with the scope of their work and the methods of inspection that they are qualified to use. No inspection organization will be qualified to perform every type of inspection using every type of approved method.

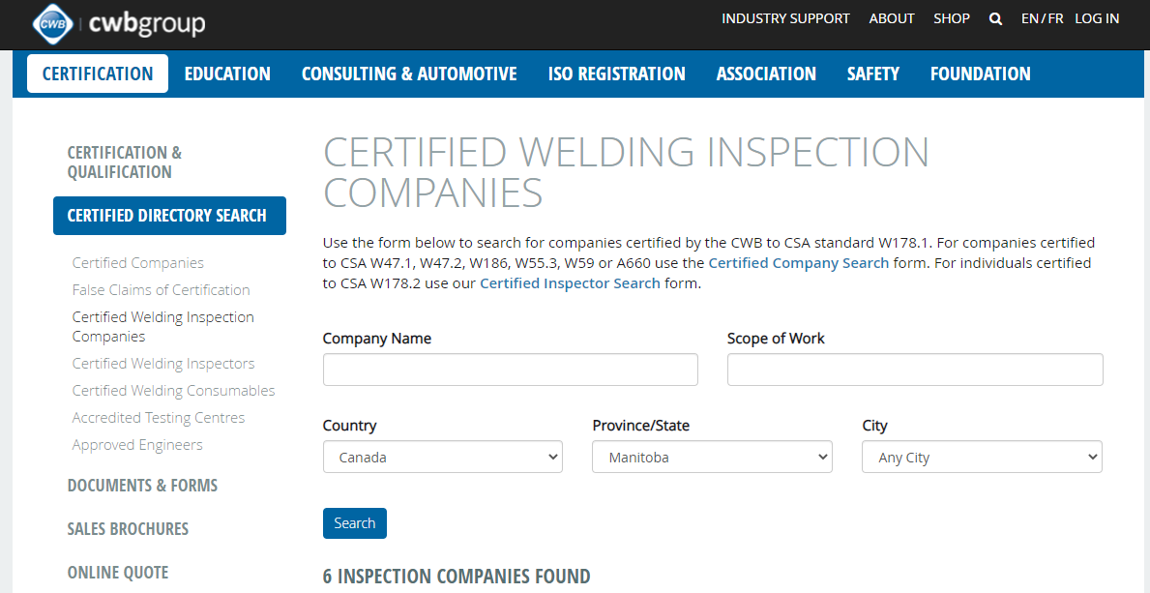

The CWB Group has an excellent online resource to navigate inspection organizations, as well as individuals. To find a Certified Welding Inspection Company navigate to the CWB Group website and find the “Certified Welding Inspection Companies” located under the Certification tab.

- From there, you can filter by country and then province (you must select the country first!).

- You can see below that there are 6 certified inspection companies here in Manitoba.

- All results are listed in alphabetical order, and include company name, contact information, as well as the scope of work and inspection methods each company is certified to perform.

PRO TIP: Not all inspection service providers are certified to perform the same work. Before working with an inspector, ensure that the work you are asking for is something that your inspection service provider is certified to perform.

What Makes a Certified Inspection Organization Certifiable?

In the fewest words possible, to become certified an inspection company must have:

- Documented appropriate inspection procedures for the scope of work and inspection methods,

- A training program for their inspectors,

- Certified inspectors and/or certified NDT testing equipment operators as needed,

- A welding supervisor who is a full-time employee and certified level three welding inspector, who has authority and control over the inspection process. This supervisor shall be qualified to perform the scope and methods of inspection of the inspection organization.

- If the supervisor is not qualified to perform every aspect included in the scope of work, the inspection organization must employ a secondary level two or level three inspector who is qualified in the aspects that the supervisor is not.

What about the Inspectors?

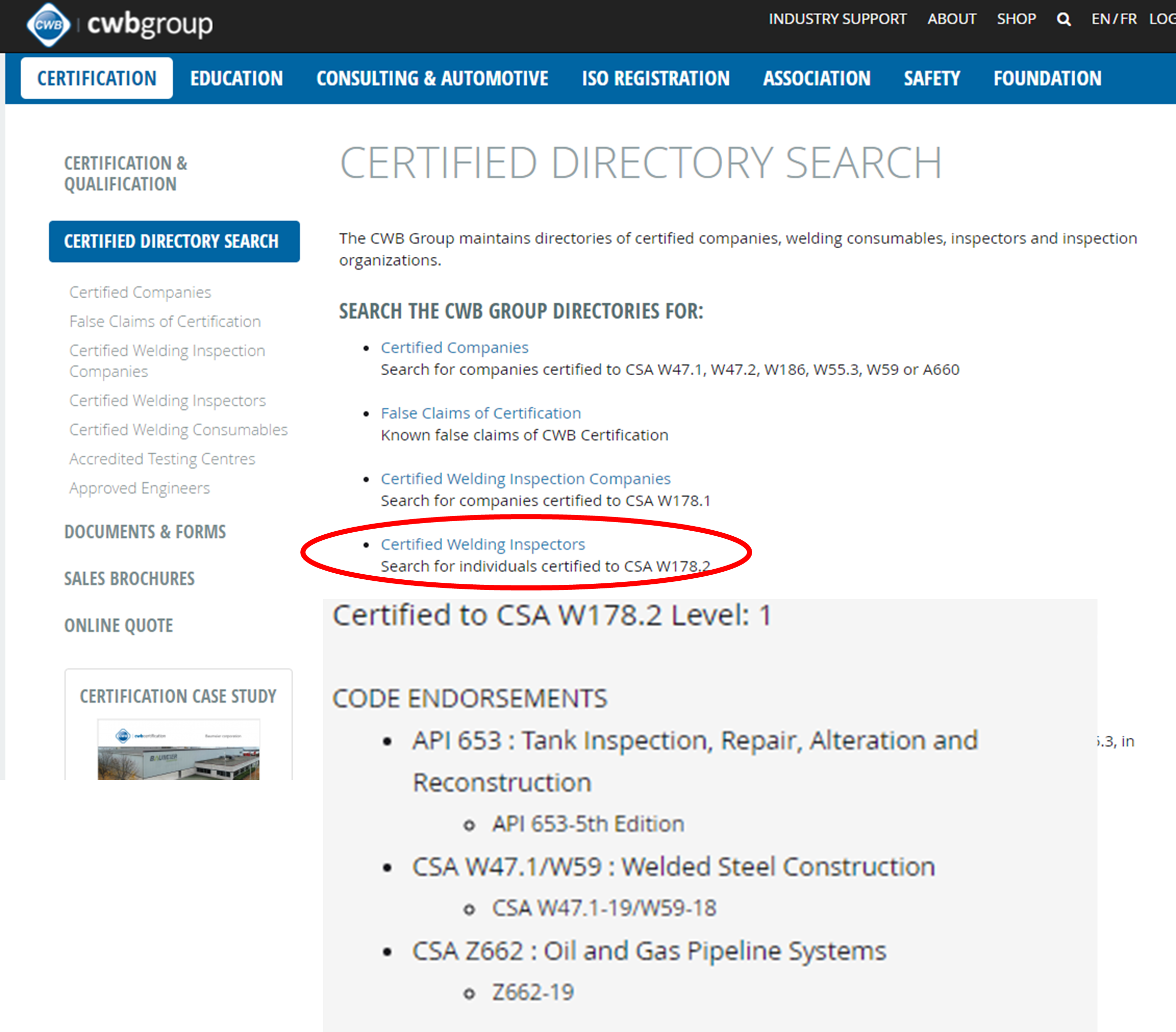

It’s good practice to ensure that the inspector who has arrived on site is actually qualified to perform your inspection. Using the CWB Certified Inspector tab is just as important as confirming that an organization is qualified.

When you search for a specific inspector, you will see their full name, their inspector number, and a list of code endorsements just like this. Make sure their code endorsements match the inspection they will perform for you.

Hang on – the false inspector from the news was impersonating an engineer – not an inspector! How does this help?

Yes, in this story, this person is alleged to have impersonated an engineer, and engineers do not register with the CWB. However, they DO need to register with their provincial or territorial regulatory body (in Manitoba that organization is Engineers Geoscientists Manitoba, formerly APEGM). This regulatory body maintains a list of the working engineers in the jurisdiction and the status of their registration. This directory can be found here: https://www.enggeomb.ca/Directory.html

Engineers must be licensed in Canada to work as an engineer and that license must be current. Your local regulatory group will make every effort to keep their website directory up to date, but if you have any doubts, you can call them directly. In Manitoba the EGM can be reached at 204-474-2736.

The fallout of having cranes inspected by false inspectors can be a detrimental hazard. As a major safety resource for the manufacturing sector, Made Safe has the tools to help you maintain the safest work environment possible. Knowing the right checks can be important when having your equipment inspected – and can help prevent major equipment failure, lower the risk of injuries, and even save lives. It’s our goal that, in sharing, we help create a safer workplace for all.