Covid-19: Manufacturing Health & safety Plan – Self-isolation Exemptions to Interjurisdictional Travel

Covid-19: Manufacturing Health & safety Plan – Self-isolation Exemptions to Interjurisdictional Travel

Posted on September 18, 2020

As manufacturers in Manitoba emerge from the crisis phase of the pandemic and begin to move forward into recovery, a host of business critical requirements may necessitate travel between jurisdictions – from province to province and occasionally, from country to country.

The people that power manufacturing operations are not always found in Manitoba. From technicians and engineers to auditors and other experts, employees and contractors from jurisdictions across Canada and beyond will again be needed on site in order to keep factories operating and running safely. What follows is a list of considerations and leading practices based on the hierarchy of controls process that will safeguard our workforces, our businesses, and our province against the travel-related risks of imported pathogens.

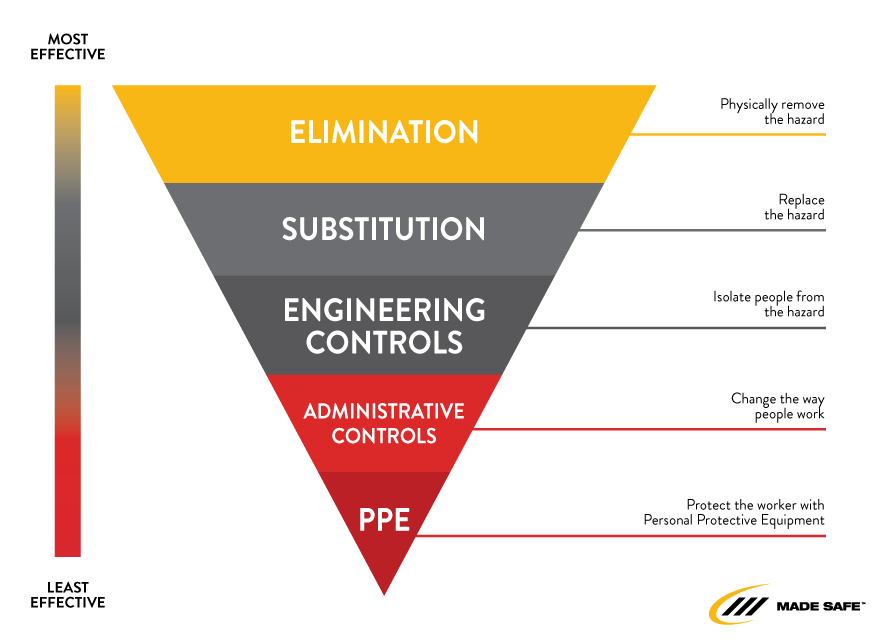

HEIRARCHY OF CONTROLS

The hierarchy of controls is a systematic approach to controlling hazards, beginning with the most of effective corrective actions and controls, moving towards the least. In order, they are elimination, substitution, engineering, administrative, and personal protective equipment (PPE).

To mitigate the risk, we first need to understand how the virus is transmitted. The SARS-CoV-2 virus that causes COVID-19 is contracted through both direct transmission (close contact with an infected person) and indirect transmission (infected person to surface to person).

To mitigate the risk, we first need to understand how the virus is transmitted. The SARS-CoV-2 virus that causes COVID-19 is contracted through both direct transmission (close contact with an infected person) and indirect transmission (infected person to surface to person).

Close contact for non-health care professionals can be considered as a person who lived with or otherwise had face-to-face contact within two metres with a probable or confirmed case for more than 15 minutes (note that this may be cumulative, i.e., multiple interactions) or had direct contact with infectious body fluids of a probable or confirmed case (e.g., was coughed or sneezed on): http://www.bccdc.ca/health-professionals/clinical-resources/case-definitions/covid-19-(novel-coronavirus).

Arranging for interjurisdictional travel from zones not exempted by health orders may be possible on a case-by-case basis, at the discretion of the public health officer, with prudent and suitable risk mitigation procedures. Manufacturers should be aware that both federal as well as provincial health orders may apply. For example, while Public Safety Canada, upon consultation with the Public Health Agency of Canada (PHAC) and other public and private Critical Infrastructure (CI) Stakeholders provides guidelines that clarify that there are no entry limitations for healthy asymptomatic personnel performing essential work as defined by the Chief Public Health Officer of Canada, nor is there a federal requirement that they quarantine themselves for the 14-day period that begins on the day on which they enter Canada as long as they meet the specified criteria (https://cme-mec.ca/wp-content/uploads/2020/07/Guidance-Information-on-Essential-Workers-Crossing-the-Border.pdf), provinces or territories may have additional quarantine measures that must be followed.

For manufacturing, health and safety best practices include the following, which may be supplemented with additional measures based on the situation itself: Manitoba, for instance, requires a 14 day quarantine for all persons not exempted by the public health orders.

RISK MITIGATION (ELIMINATION): NECESSARY WORK

To help reduce the risk in the planning phase, first confirm that the proposed work is necessary. Is the work itself urgent and critical to operations? Can it be postponed to a later date? Essential services such as new construction, new equipment installations, essential equipment repairs, troubleshooting and systems support should be able to go ahead safely with the correct precautions in place. Safety and other accreditation maintenance audits may or may not be able to be postponed during the pandemic while retaining certification. Sales calls, in person demos, and non-mission critical audits should be evaluated against safety and operational needs with serious consideration given to other options for achieving the goals of those activities.

RISK MITIGATION (SUBSTITUTION): REMOTE FACILITATION

If the activities are necessary, can they be performed remotely using technology? Troubleshooting electronic systems using a local technician communicating to an expert via Zoom, Teams, or Skype should be considered. Training operators on how to run a newly installed piece of equipment is critical and may not be able to be performed entirely via technology. During necessary activities where social distancing will be difficult, PPE such as face shields and face coverings should be added to the procedures outlined in your COVID-19 policy.

RISK MITIGATION (ENGINEERING): TRAVEL POLICIES

Next, consider the COVID-19 statistics for the area that the visitor is coming from and what the level of risk is for that area. Health Canada provides these statistics https://health-infobase.canada.ca/covid-19/epidemiological-summary-covid-19-cases.html?stat=num&measure=total#a2, which will help guide this discussion on risk. Where possible, choose technicians and service personnel from areas where the total case count graph line has plateaued or is trending downward. Areas where the total case count graph line is still trending up carry more risk.

To mitigate risks during travel, plan what route and medium for travel the visitor will take. Avoid high risk areas during stop overs in favour of direct routes. Avoid public transportation, where disinfection opportunities are regulations are less stringent, including from the airport to the hotel or to the facility. Choose direct flights with airlines that use pre-boarding screening, require face coverings and disinfect between flights. Avoid hotels in high-risk areas. Vetting protocols and procedures should be a priority when selecting accommodations.

RISK MITIGATION (ADMINISTRATION): SITE SCREENING

Ensure that your COVID-19 policies, including pre-screening and the procedures required once onsite, are discussed during the planning phase. Moreover, the visitor (whether they are an employee or a contractor) should review the organization’s COVID-19 safety policies and sign documentation attesting to the fact that they are aware and have received training on the organization’s these policies prior to visiting the site. Any person who is symptomatic or who has been in contact with anyone diagnosed with COVID-19 in the past 14 days must not be allowed on site at any time.

RISK MITIGATION (ALL, INCLUDING PPE): SITE HAZARD REDUCTION

To eliminate the risk of direct transmission from extra jurisdictional persons in a manufacturing facility, eliminate the opportunities to come into contact with personnel from the home facility:

- Create a separate work area as best as possible. Measures may include the use poly sheeting or other materials to create physical barriers around the work area and/or path from the work area to the entrance. If feasible, consider additional measures such as a separate entrance to the work area or moving the equipment or product to an area of the facility when doing so does not create significant challenges to

workflow. - Adding sufficient exhaust ventilation direct to the outside (fan in the doorway, etc.) to this area can create a negative pressure

environment and ensure no respiratory droplets leave the area. The virus cannot move against air currents. Add signage at the exhaust point to keep staff away.

Provide temporary washroom facilities for the exclusive use of the visitor. Providing portable toilets and hand washing stations next to their separate entrance and hand sanitizer will meet the needs of the visitor and maintain separation. - In Manitoba, the safety legislation requires that workers, including contractors, not be permitted to eat or drink in contaminated areas. Ensuring that there is a separate space inside the work area for breaks is important.

- Adding the support of a company that can provide large scale disinfection to ensure that the separate work area and equipment or materials being worked on are disinfected after the visitor has left is ideal. Allowing the area to sit undisturbed for an appropriate length of time based on the surfaces in the area for the virus to die off and engaging in small scale disinfection can also be effective. To facilitate local supply chains, many provinces now offer tools like the B2B Manitoba app, which create online marketplaces that bring together buyers and sellers of not only PPE, but other health and safety products and services like decals, barriers, cleaning and disinfection services and more.

PROVINCE OF MANITOBA WEBSITE

There are various web sites the province has to address a variety of issues but there is one page that outlines the expectations for out of province workers that can be useful. Please feel free to share with others and pass on the link if you think it would be useful

https://www.gov.mb.ca/covid19/business/out_of_province.html.

APPLY FOR AN EXEMPTION TO THE SELF-ISOLATION RULE

For more information about exemptions and support with the process for business necessary inter-jurisdictional travel please contact

our offices at edj.sru@gov.mb.ca.

For more information

Download the full Employee COVID-19 positive test result: protocols and guidelines here.